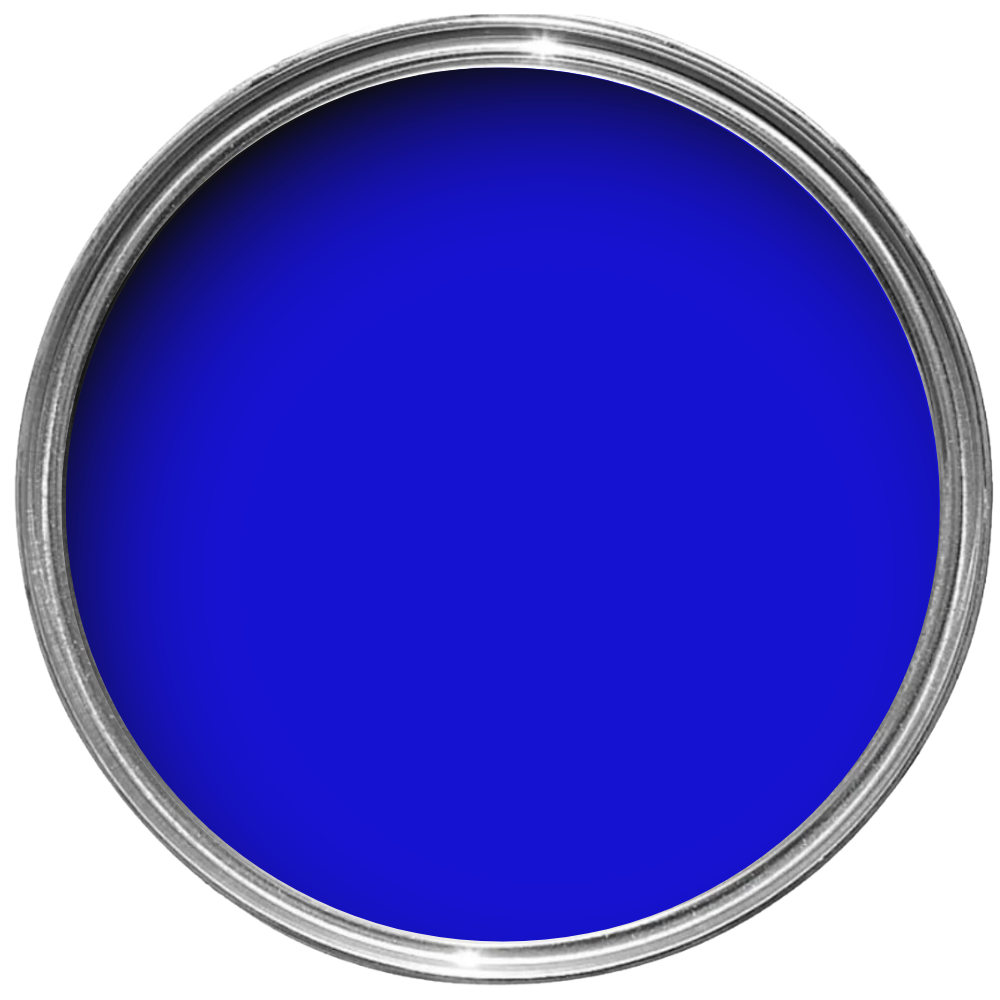

Skip & Container Paint for Anti-Corrosive Enamel 20.0 kg

Why Choose Our Products?

Heavy-duty anti-corrosive solvent-based enamel

Excellent rust abrasion and impact resistance

Smooth high-gloss industrial finish

Suitable for spray brush or roller application

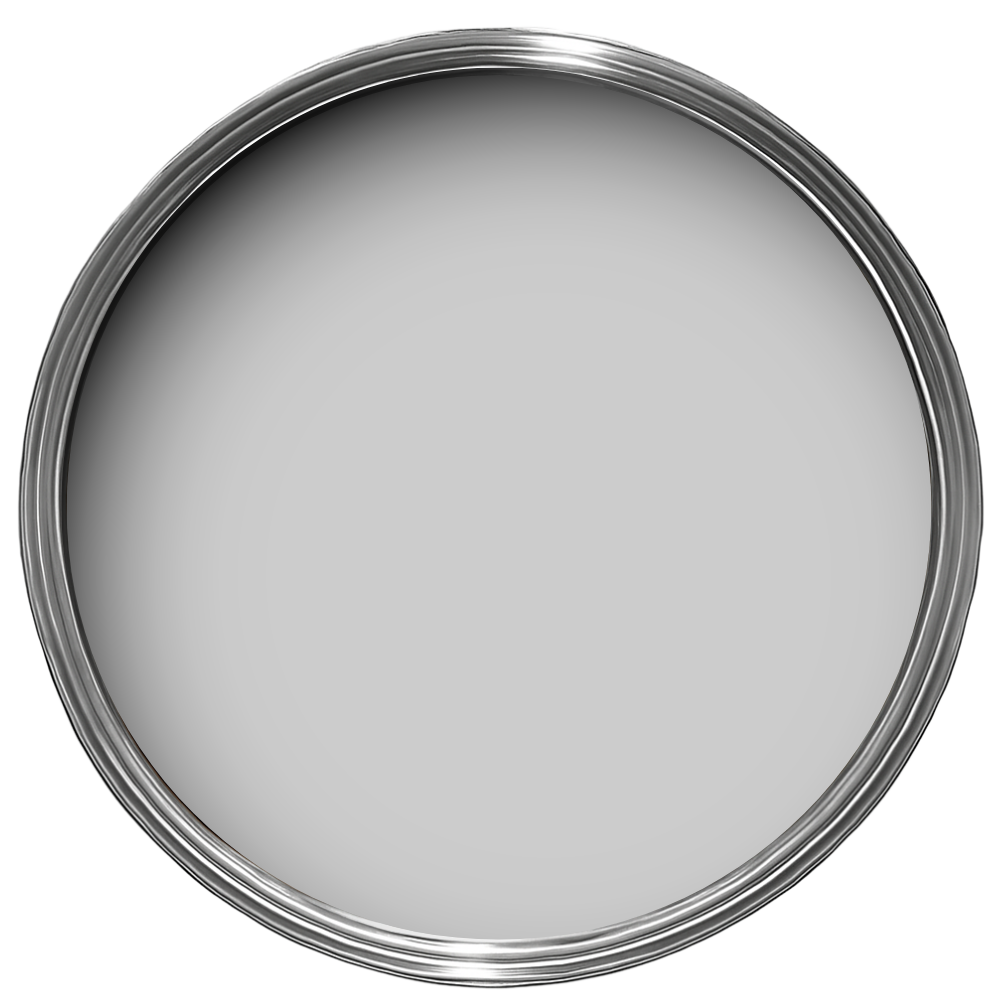

12 popular industrial colours with quick UK dispatch

Our Skip & Container Paint is a professional-grade, anti-corrosive industrial enamel formulated to protect steel skips, shipping containers, waste bins, and other heavy-duty metal equipment exposed to harsh outdoor conditions. Using a durable long-oil alkyd resin system combined with advanced rust-inhibiting pigments, it forms a tough, weatherproof oxide gloss coating that resists corrosion, chipping, and daily abrasion.

This high-performance enamel self-levels to a smooth, easy-clean gloss finish, giving metal surfaces a professional look while locking out moisture and environmental contaminants. It is engineered for excellent adhesion over correctly primed steel and is compatible with brush, roller, or airless spray application, allowing both small touch-ups and large industrial projects to be completed efficiently.

Ideal for use in construction, waste management, transport, and marine environments, Skip & Container Paint provides long-term colour retention and protection even in demanding UK weather. Manufactured under ISO 9001 standards, each batch is quality-checked for consistent viscosity, sprayability, and colour fidelity, ensuring dependable results every time.

Suitable Substrates

Skip & Container Paint can be applied to a wide range of properly prepared surfaces, including:

-

Steel skips and shipping containers: Protects against rust and impact damage in harsh outdoor conditions.

-

Metal waste bins and industrial equipment: Creates a smooth, easy-clean finish that resists dirt and moisture.

-

Metal cladding and primed steel structures: Bonds strongly over compatible anti-corrosive primers for long-lasting protection.

-

Concrete, brick, and timber (primed): Provides a durable decorative finish when correctly sealed or primed.

Bare or rusty steel must be treated and primed with a compatible anti-corrosive oxide primer to achieve maximum adhesion and rust resistance.

Coverage & Pack Sizes

Our Skip & Container Paint provides an economical spread rate of approximately 6–8 m² per litre per coat on smooth metal surfaces.

Pack sizes: 5 L, 10 L, and 20 L, suitable for both small maintenance jobs and large industrial applications.

Drying & Curing Times

-

Touch dry: 6–8 hours at 18 °C

-

Recoat: After 6–8 hours

-

Full cure: 7 days for maximum hardness and chemical resistance

These times may extend in cooler or humid conditions.

Storage & Clean-Up

Store the product tightly sealed between 5 °C and 30 °C, away from ignition sources and direct sunlight.

For spraying, thin with up to 15% white spirit to achieve the desired spray pattern.

Clean brushes, rollers, and spray equipment immediately after use with white spirit to maintain tool life.

Batch Consistency

For large or multi-container projects, always order the full quantity in a single batch to ensure consistent colour match across the entire job.

Safety Guidance

This is a solvent-based paint containing flammable components. Always use in well-ventilated areas and keep away from open flames or sparks.

-

Wear protective gloves, eye protection, and a suitable respirator if spraying to avoid inhalation of vapours.

-

Avoid skin contact and dispose of all waste material in accordance with local environmental regulations. Refer to the product Safety Data Sheet (SDS) for full safety instructions.

| Property | Value |

|---|---|

| Components | Single-pack (1-part) |

| Base | Long-oil alkyd resin |

| Finish | High-gloss oxide enamel |

| Recommended Coats | 2 |

| Wet Film Thickness | 100 µm (≈ 50 µm DFT) |

| Coverage | 6–8 m² per litre per coat |

| Touch Dry | 6–8 h @ 18 °C |

| Recoat Time | 6–8 h @ 18 °C |

| Full Cure | 7 days |

| Property | Value |

|---|---|

| Application Tools | Brush, roller, airless/compressor spray |

| Clean-up | White spirit / PU thinner |

| Shelf Life | 24 months unopened |

| Suitable Substrates | Steel, concrete, brick, timber |

| VOC | < 450 g/L |

| Interior/Exterior | Suitable for both |

| Primer Required | Yes – on bare or rusted metal |

DATA SHEETS AND PRODUCT FILES

Below are all the products and files we have on this coating. If you require any more information on this product, please email us at support@tradesuppliesuk.co.uk or call us on 07929 525648 and one of our staff members will do their best to try and provide you with the information needed.

FILES AND DATA SHEETS

Frequently Asked Questions

Select Variant and Order

Skip & Container Paint for Anti-Corrosive Enamel - 20 Litres / Light Grey is backordered and will ship as soon as it is back in stock.