Floormaster Polyurethane Floor Paint for Durable Floors 20.0 kg

Why Choose Our Products?

Heavy-duty industrial polyurethane floor coating

Gloss film shrugs off oil & petrol

Optional silica anti-slip texture

12 workshop-ready colours

Brush roll or spray – easy white-spirit clean-up

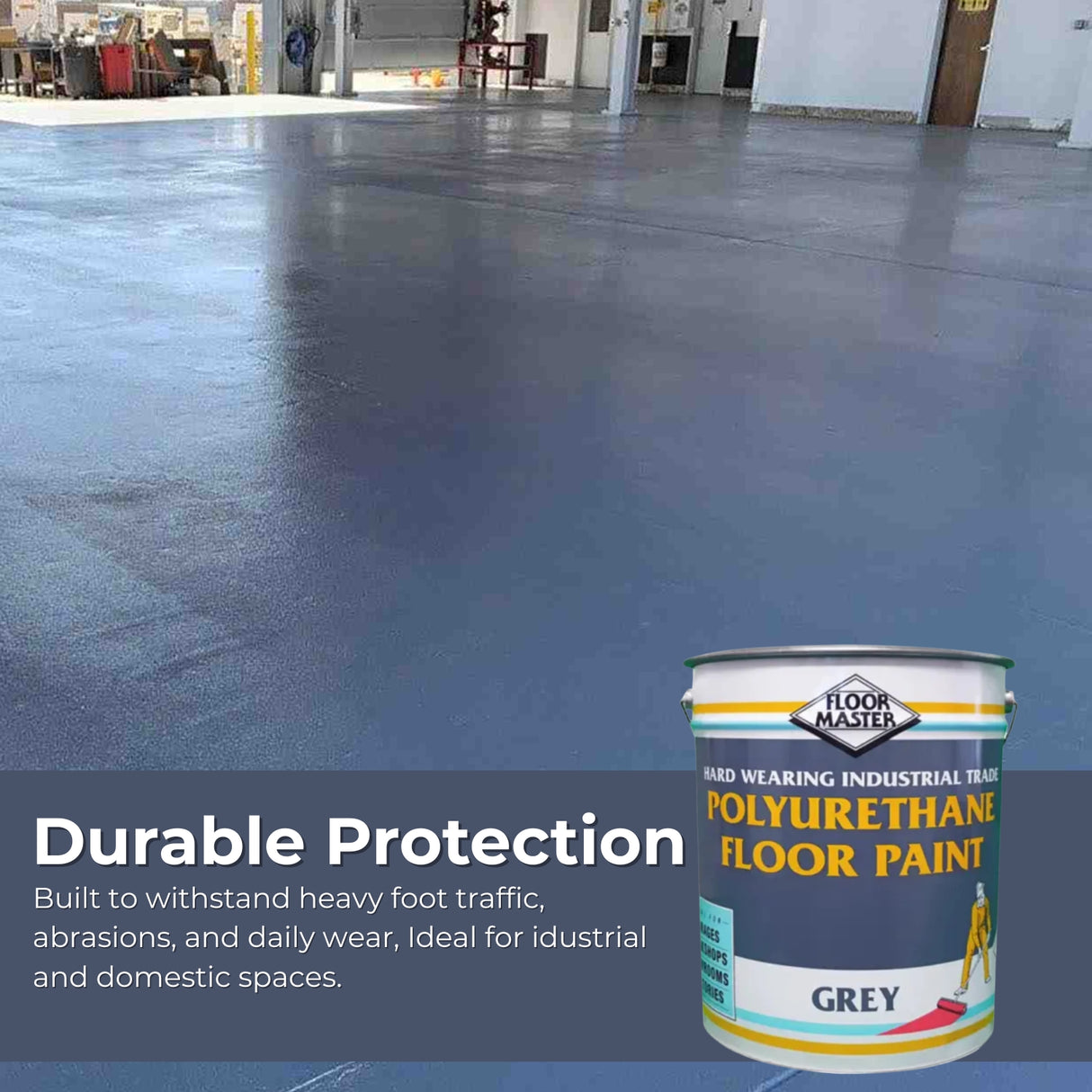

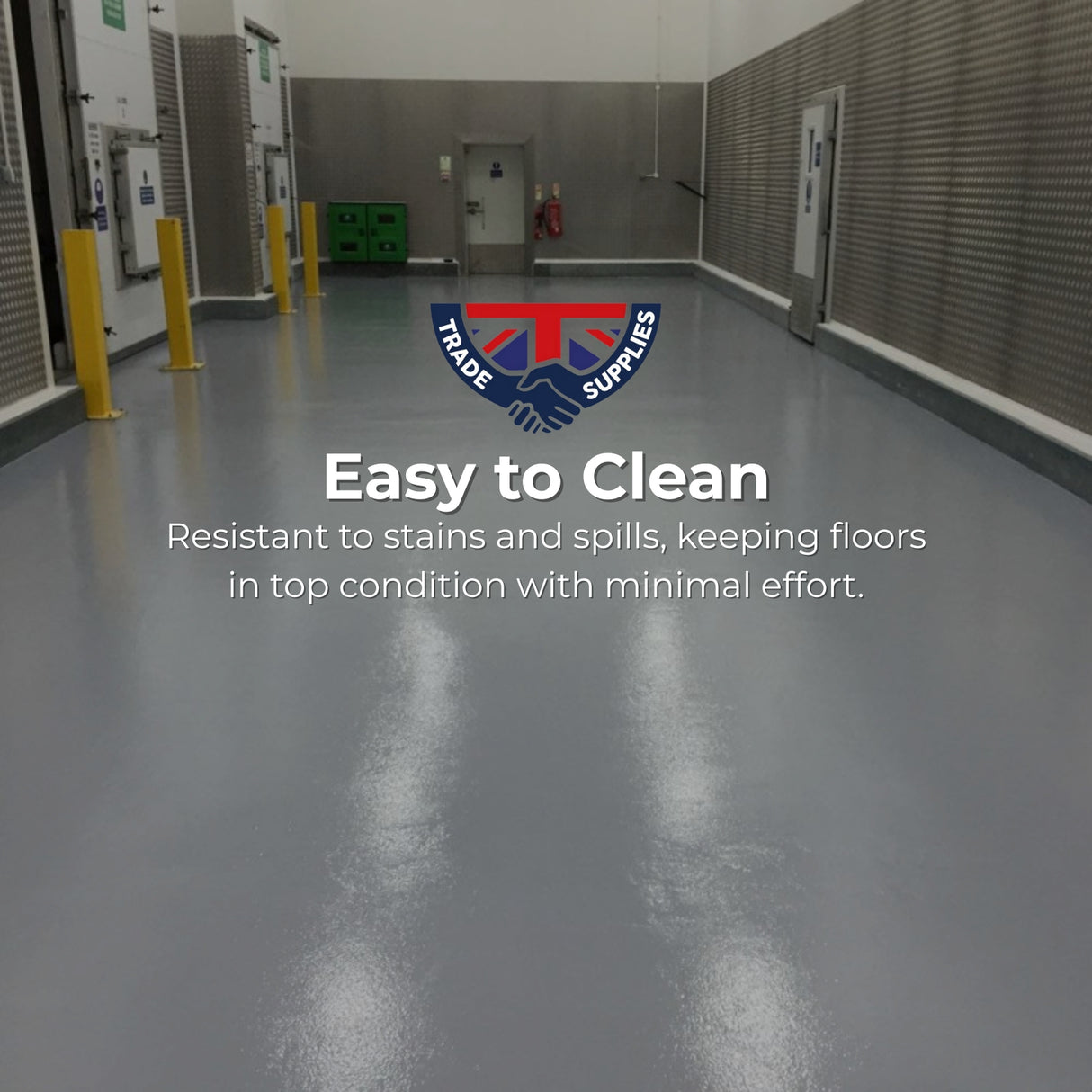

Floormaster Polyurethane Floor Paint is a professional-grade concrete and garage floor coating developed for areas exposed to constant wear, chemical exposure, and heavy traffic. Formulated with a long-oil polyurethane resin, this solvent-based, single-pack paint delivers a tough, glossy finish that matches tyre scuffing, oil stains, cleaning agents, and day-to-day use in workshops, warehouses, and storage facilities.

Unlike cheaper acrylic floor paints, Floormaster polyurethane cures into a dense protective layer that locks down dust, resists penetration from oils and fuels, and stays attractive for years with minimal maintenance.

An anti-slip version is available for extra safety: simply stir in the supplied silica sachet to create a fine, textured satin finish that improves grip on ramps, loading bays, and wet working zones. This makes it especially popular for vehicle workshops, industrial corridors, and factory floors where safety compliance is necessary.

For bare or polished concrete substrates, we recommend priming with Floormaster Polyurethane Floor Primer & Sealer before application to ensure maximum adhesion and durability. Two thin coats then deliver an approximate 50 μm dry film thickness for a long-lasting finish that outperforms standard trade coatings.

Suitable Substrates:

Floormaster Polyurethane Floor Paint is highly versatile and can be applied to:

-

Concrete and cement screeds: ideal for garages, warehouses, and storage units. Power-floated slabs should be ground or etched before priming.

-

Block paving and porous masonry: effective for utility spaces, service yards, and storage areas.

-

Timber floors: provide a washable, durable finish for wooden workshop floors.

-

Mild steel and prepared metal: can be applied when appropriately abraded and primed with a compatible basecoat.

Note: not recommended directly over existing solvent-based floor paints without complete removal or successful compatibility testing.

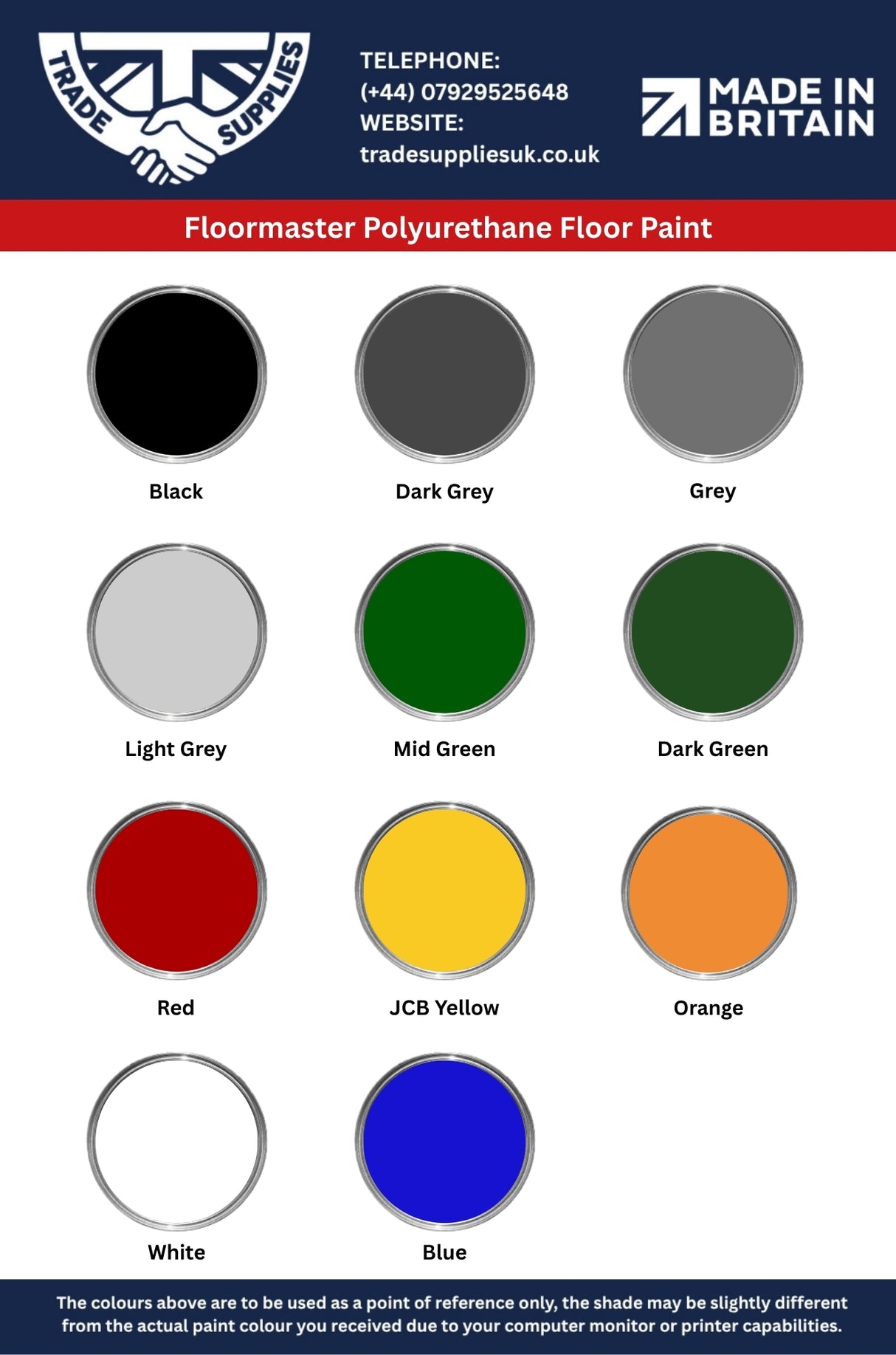

Available Colours:

Choose from 12 durable workshop-ready shades designed to suit industrial safety and commercial aesthetics:

Black, Dark Grey, Grey, Light Grey, Mid Green, Dark Green, Post Office Red, Red, JCB Yellow, Orange, Blue, and White. For specialist projects, custom BS 4800 and RAL colours are available on orders of 100 litres or more, allowing complete alignment with safety zoning or branding requirements.

Coverage & Spread Rate:

-

6–8 m² per litre per coat on smooth, well-prepared concrete.

-

A 5L tin covers approx 15 m² with two coats.

-

A 20L tin covers approx 60 m² with two coats.

For the best finish and maximum lifespan, always apply two thin coats at right angles and order the full volume in one batch to ensure colour consistency.

Drying & Curing Times (@ 18 °C):

-

Touch dry: 4–6 hours

-

Recoat window: 6–8 hours

-

Light traffic: 24 hours

-

Vehicle traffic: 72 hours

-

Complete cure and chemical resistance: 7 days

This fast turnaround allows areas to be in light use within a day, offering full industrial performance after a week.

Storage & Thinning:

Store securely between 5 °C and 30 °C, away from heat and flame sources. Always reseal tightly between uses. Tools and rollers can be cleaned with white spirit while still wet. If thinning is required, use White Spirit or Turpentine Substitute sparingly (no more than 5%) to maintain coverage and performance.

Packaging notice:

During peak demand, tins may occasionally be supplied in plain white packaging with printed product labels. The product quality and performance remain identical.

Safety notice:

This is a solvent-based, flammable floor paint for professional use. Always apply in well-ventilated areas, avoiding sparks, heat, and flames. Wear gloves, eye protection, and a respirator if required. Prevent prolonged skin contact and inhalation of vapours. Keep children out of reach and dispose of waste responsibly. Consult the product Safety Data Sheet (SDS) for full health and safety guidance.

| Property | Details |

|---|---|

| Components | Polyurethane-based resin |

| Base Type | Solvent-based |

| Finish | Gloss |

| Theoretical Coverage | 6–8 m² per litre per coat |

| Number of Coats | 2 |

| Coating Thickness | Dependent on the application method and surface porosity |

| Suitable Substrates | Concrete, wood, metal |

| Use Case | Interior and exterior |

| Touch Dry Time | 4–6 hours |

| Property | Details |

|---|---|

| Overcoatable | After 24 hours |

| Pot Life | Not applicable |

| Primer Required? | Recommended for porous surfaces |

| Colour Options | Multiple color options available |

| Application Method | Roller or sprayer |

| Cleaner / Thinner | Trade Paints PU Thinner |

| Shelf Life | 12 months (unopened) |

| Sizes Available | 5 L, 20 L |

Frequently Asked Questions

Select Variant and Order

Delivery within 24 to 48 hours

Floormaster Polyurethane Floor Paint for Durable Floors - 20 Litres / Black / Anti Slip is backordered and will ship as soon as it is back in stock.